Kanthal’s steel plant in Hallstahammar produces ingots of special Fe- and Ni-base alloys. These ingots are hot rolled into smaller billets and slabs in the ingot rolling mill. Before rolling, different ingot grades are heated to specific temperatures in the typical range of 1,150–1,300°C (2,100–2,370°F). Traditionally, this was done in large pit furnaces.

Roger Berglund and Stephanie Stockmeier together with Peter Vabulis, Flow Manager at Kanthal's ingot rolling mill.

Roger Berglund and Stephanie Stockmeier together with Peter Vabulis, Flow Manager at Kanthal's ingot rolling mill.

However, pit furnaces are heavy-mass structures with limited temperature flexibility. Some ingots are sensitive to thermal shock and may crack if put directly into a hot pit furnace. Another challenge was the need to heat longer pieces of continuously cast materials. To address this, Kanthal decided in 2012 to build a car bottom furnace as a supplementary ingot heating solution, using lightweight thermal insulation and electric heating.

“It was important to be able to heat the furnace from room temperature to 1,250°C (2,280°F) at a set rate,” explains Stephanie Stockmeier, Senior Process Development Engineer at Kanthal. “Some materials need to start heating from a low temperature to be rolled. The ability to heat from 20°C to 1,250°C (68°F to 2,280°F in the same furnace is a huge advantage.”

How Kanthal built the furnace

Choosing electric heating instead of gas delivers higher energy efficiency and superior temperature control. With fossil-free electricity, the furnace operates virtually without CO₂ emissions.

After purchasing a car bottom shell from a furnace manufacturer, Kanthal installed Fibrothal® insulation and Kanthal® APM metallic heating elements. Choosing electric heating instead of gas delivers higher energy efficiency and superior temperature control. With fossil-free electricity, the furnace operates virtually without CO₂ emissions.

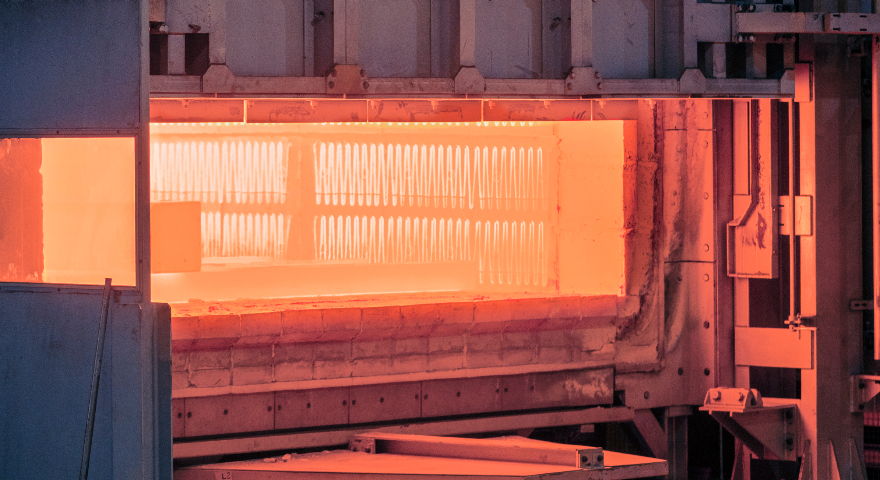

The car bottom furnace with electric Fibrothal® heating modules at Kanthal's ingot rolling mill.

The car bottom furnace with electric Fibrothal® heating modules at Kanthal's ingot rolling mill.

A faster and more reliable process

The car bottom furnace also improved speed and process reliability.

“It’s a faster process,” says Stockmeier. “We can start the furnace at room temperature, gradually heating ingots to above 1,200°C (2,192°F) for rolling the next day, and then return to room temperature the following day. The elements are so reliable that they last even when operating across the full temperature range.”

The Fibrothal® lightweight insulation reduces thermal mass, improves temperature regulation, and decreases energy waste.

“With lightweight insulation, we minimize the required energy input every time we heat up or cool down the furnace,” says Roger Berglund, Senior Expert at R&D, Kanthal. “The furnace becomes faster and easier to control; that’s the benefit of fiber insulation.”